|

Reports to: Director of R&D Department Name: Research and Development Location: Portland, OR GENERAL SUMMARY DESCRIPTION: This individual is responsible for assisting Food Technologists with samples for customers. They will also assist in the development of new products for customers and the revision of existing products as assigned by the Director R&D. This position shall adhere to Oregon Spice Company Food Safety and Quality Fundamentals. ESSENTIAL FUNCTIONS AND BASIC DUTIES: INCLUDE BUT ARE NOT LIMITED TO: To perform this job successfully, an individual must be able to perform each essential duty satisfactorily. The requirements listed below are representative of the knowledge, skill, and/or ability required. Reasonable accommodations may be made to enable individuals with disabilities to perform the essential functions. R&D

MINIMUM QUALIFICATIONS EDUCATION/CERTIFICATION: Pursuing Bachelor’s degree with a Food Science. EXPERIENCE: NA REQUIRED KNOWLEDGE:

To apply, please send your resume to Jennifer Marcotte - Director of Research and Development [email protected]

0 Comments

Seattle, WA

Posted:11/27/2023 Over 40 years ago, Food Lifeline started as an organization with the mission of providing food assistance to the community by serving as a clearinghouse for donated and government-provided food. As the organization grew, its mission, commitment, and programs evolved to become much more. Food Lifeline grew beyond a focus on the logistics of sourcing, storing, packing, and distribution of food to an organization that deeply understands the importance of both ensuring people have adequate access to food, while working to address poverty as a leading driver of hunger. Food Lifeline provides nutritious food to 1.37 million people facing hunger by sourcing nutritious food from a variety of food industry partners. The organization distributes through a network of 350 food banks, shelters, and meal programs, enabling it to provide the equivalent of more than 282,000 meals every single day. As Food Lifeline looks to the future, they seek a CEO who will continue to inspire growth, increase awareness, and actualize a comprehensive vision for the central role Food Lifeline plays in ending hunger across western Washington. The next leader will maintain their current momentum and elevate the profile of Food Lifeline across western Washington and within the Feeding America network. The CEO will have the opportunity to advance Food Lifeline’s mission of providing healthy solutions to end hunger in their community in new and exciting ways. The ideal candidate will have significant experience in leading strategic and high-level decision-making, particularly in times of organizational growth and expansion of impact. The candidate will be adept at using keen interpersonal skills to coalesce multiple external stakeholders around common goals. They must embody the highest ethical standards and demonstrate a balance of business savvy with a commitment to responsible, people-focused program delivery. A demonstrated ability to develop and maintain highly professional relationships with business, civic and nonprofit leaders is required. The successful leader must demonstrate an unwavering commitment to equity, diversity, and inclusion through words and actions and is attuned to social factors that impact the systemic issues behind and root causes of food insecurity. This individual will demonstrate a history of accomplishment in the DEI space and will have helped their organization(s) develop and implement DEI strategy, initiatives and activities. Candidates must demonstrate a history of building, supporting, and developing a diverse team and have experience sharing power while collaborating with a diversity of internal and external constituencies to achieve results. The compensation range for this position annually is between $260,000 - $325,000. Medical, Dental, Vision, Life, Short-Term, Long-Term Disability Insurance Options; 401(K) retirement savings plan; Flexible Spending Account; Wellness and Education Reimbursement Policy; Generous PTO, Paid Holidays. Family Bereavement leave. Full job posting Apply Here Base Salary: $80,000

RESPONSIBILITIES INCLUDE BUT ARE NOT LIMITED TO:

INTERESTED? Please send cover letter and resume to: Main Contact :Yujin Cho, QA Team Leader | [email protected] Secondary Contact: Jay | HR Manager | [email protected] NOTE: Please have them reference the Oregon Section of IFT or Jose Guerrero when applying. Our Mission

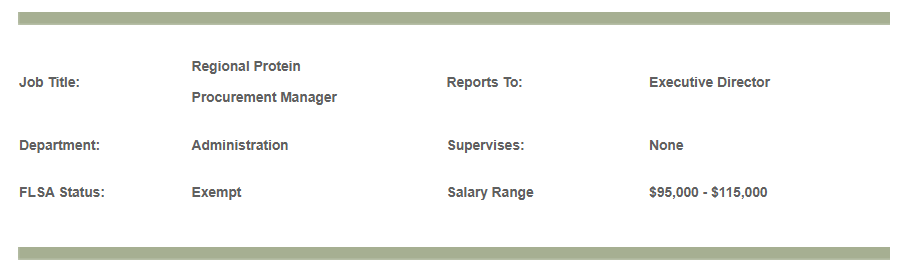

Feeding the Northwest gathers food produced in the Northwest and shares it through food banks nationwide to people facing hunger. Our Vision We envision fully nourished communities supported by a deeply collaborative Northwest food bank network invested in optimizing its food resources and deep teamwork for the benefit of all. Our Values • Openness, honesty, and integrity • Respect and support for our neighbors in need • Community partnerships and strength through collaboration • Stewardship and accountability • Respect and appreciation for the gifts and talents of our co-workers and colleagues Job Summary This position is responsible for the procurement of protein foods (poultry, beef and milk) that will benefit our Northwest food banks. This individual must be highly motivated and ambitious in prioritizing their day-to-day activities. The successful person must have a strong working knowledge of the protein industry, with prior working experience necessary. This person will work with a varied list of food companies in the protein industry, with the goal of sourcing zero cost to low-cost truckloads of protein foods for our Northwest food banks. Essential Job Duties/Key Accountabilities To perform this job successfully, an individual must be able to satisfactorily perform each of the essential duties/responsibilities listed below. Reasonable accommodation may be made to enable individuals with disabilities to perform the essential duties/responsibilities of this job. • Lead the planning and sourcing activities around protein foods. • Work with key staff at NW food banks to identify protein needs; current relationships; and current landscape of protein opportunities and challenges. • Build and maintain vendor relationships within the protein industry that focuses on procuring zero cost to low-cost truckload quantities. • Develop strong working relationships with cross functional leaders with food banks in the Northwest, the Feeding America network, and staff at Feeding America. • Monitor and stay current on industry trends and share pertinent information with NW food banks. • Process all orders through Feeding Washington’s order system, including sending out sales and shipper confirmations and invoices. • Track spending of any related protein grants. • Perform other responsibilities as assigned. Education and Experience • Bachelor’s degree from a four-year college or university or equivalent related professional experience and/or training. Job Requirements • Prior working experience in the protein industry a must. • Strong leadership qualities and the ability to use sound judgment in making decisions. • Ability to establish and maintain effective working relationships with all contacts inside and outside of the organization. • Ability to work independently with successful results a must. • Excellent verbal and written communication skills. • Strong organizational skills, with the ability to multi-task multiple projects at one time. • Excellent Microsoft Office 365 skills. • This position is a remote position; however, the ideal candidate would be located with the Northwest states of Washington, Oregon or Idaho. • Travel is expected, mostly within the Northwest states. Average 1 week of travel out of each month. Interested candidates may send their cover letter and resume to Rod Wieber, [email protected] About Us

Symrise is a global supplier of fragrances, flavors, food, nutrition and cosmetic ingredients. Its clients include manufacturers of perfumes, cosmetics, food and beverages, pharmaceuticals and producers of nutritional supplements and pet food.Its sales of € 4.6 billion in the 2022 fiscal year make Symrise a leading global provider. Headquartered in Holzminden, Germany, the Group is represented by more than 100 locations in Europe, Africa, the Middle East, Asia, the United States and Latin America. The Naturals business unit, within Food & Beverage, delivers natural ingredients, obtained using various gentle processing technologies. The team of in-house agronomists carefully selects raw materials and applies best-in-class sustainable sourcing practices, to capture the highest natural properties of conventional and organic fruit, vegetables, meat, seafood, vanilla, and botanicals. Gentle industrial processes and technological know-how enable us to deliver consumer-friendly label solutions and standardized nutritional actives. Symrise can, in this way, guarantee food safety, highest quality standards, and traceability, ensuring trust all along the value chain. Symrise – always inspiring more… Your Role We are currently seeking a R&D Technology Intern at our production site in Silverton Oregon. This position will be responsible traveling to our farm sites to collect corn samples for analysis. Additional responsibilities include, data entry, sample preparation and sample shipment and other related laboratory responsibilities. This a paid internship at $14.20 per hour. • Drive to corn farms for sampling • Corn Field Sampling • Sugar Analysis • Raw material and ingredient sampling • Sample Storage • Data entry • Brix Testing • Solids Testing • Moisture Analysis • Particle Size Analysis • Color Analysis • Set up for QA Sensory • Outgoing Sample Prep About you• Clean Driving Record • Good communication skills. • Be able to communicate in written and verbal English. • Proficient in Microsoft excel and word. • Previous experience in a laboratory environment is a plus. • Ability to multitask Our offerBecome part of our open and transparent culture. It will give you the opportunity to flourish and to develop inspiring experiences that contribute to the health and well-being of consumers in 160 countries around the world. Putting our employees in focus fuels our strong company growth above market rates and makes us an excellent place to develop your career. Come join us and embark on a fascinating journey with Symrise. If you feel that you fit the above criteria, then please apply by using our online application system. Your application will be treated confidentially. We are an Equal Opportunity Employer. We do not discriminate on the basis of race, religion, color, sex, gender identity, sexual orientation, age, non-disqualifying physical or mental disability, national origin, veteran status or any other basis covered by appropriate law. All employment is decided on the basis of qualifications, merit, and business need. APPLY ONLINE Research & Development Manager, Food Manufacturing

Portland, OR (area), Onsite, Relocation Assistance Primary Purpose: Oversee and participate in product and process development of fully cooked protein products. Essential Duties and Responsibilities: 1. Assist Director of R&D to supervise R&D staff, including training and overseeing of daily activities in the pilot plant 2. Investigate opportunities for continuous improvement in current products and production processes 3. Write product formulations 4. Conceive and develop new meat products to fit our customer’s needs 5. Research ingredients and food technologies that are pertinent to the meat industry 6. Assist Director of R&D in ingredient management, ingredient rationalization, and ingredient testing 7. Support the maintenance of electronic database of projects and formulations and timely documentation of results in database note files. Generate simple format reports, as directed. 8. Assist with duties of Director of R&D when Director is absent 9. Create ingredient statements and nutritional information for new products 10. Track R&D project progression and success rate 11. Source new ingredients and build relationships with ingredient suppliers 12. Monitor first production runs 13. Work with sales on developing customer relationships, educating customers on our capabilities, conducting demonstrations and customer visits Minimum Qualifications: 1. A bachelor’s degree in food science, meat science, animal science, or related field. Experience in cooked meat commercial production or a meat lab preferred. 2. Speak, read, and write English fluently and persuasively 3. Basic computer skills, including Microsoft office suite and Excel in particular 4. Basic arithmetic Send Replies to: Connie Dorigan ([email protected]) Please send your Resume as a Word.doc with the title of the position in the subject line. You must be authorized to work in the United States now and in the future without sponsorship Come work with Tofurky! We are the Nation’s leading manufacturer of plant-based proteins and dairy-free cheeses. Our range of 35+ products can be found in more than 25,000 grocery stores throughout North America, the UK and Australia. We’re on a mission to erase the myth that people have to make a choice between enjoying tasty food OR taking care of themselves and the planet. We can do both.

Tofurky is looking for a Quality Assurance (QA) Manager to join our QA Team. The QA Manager will be responsible for overseeing the food safety and quality systems within Tofurky’s plant operations located in Hood River, OR. As an integral member of the QA Team, you’ll work with a core quality assurance team, as well as working cross-functionally to maintain, develop and enhance our food safety programs. This is an onsite role. What you’ll do: The QA Manager will be responsible for the implementation and maintenance of Tofurky’s various food safety programs including Good Manufacturing Practices (GMP’s), HACCP plan(s), BRCGS compliance, and FDA compliance. The successful candidate will be the team leader of the operationally focused QA and Sanitation teams and will work to address gaps and find opportunities for improvement in the food safety programs. As a keystone member of the QA Team, you use your tenacity and strong understanding of QA practices to problem solve food safety and quality related issues. This role requires a high level of program management skills, balanced with active time on the plant floor. Responsibilities include:

We know you’re valuable and we’ll work hard to keep you challenged. The qualified candidate will receive:

How to apply: Please submit application and upload your resume online at https://tofurky.com/careers/ Currently, The Tofurky Company does not support immigration processing or provide Visa sponsorship. All applicants must be able to provide legal proof of their eligibility to work in the U.S. The Tofurky Company values a diverse workforce. Women, people of color, people with disabilities, and members of the LGBTQ community are strongly encouraged to apply. The Tofurky Company provides equal employment opportunities (EEO) to all employees and applicants for employment without regard to race, color, religion, sex, national origin, age, disability, or genetics. In addition to federal law requirements, The Tofurky Company complies with applicable state and local laws governing nondiscrimination in employment in every location in which the company has facilities. This policy applies to all terms and conditions of employment, including recruiting, hiring, placement, promotion, termination, layoff, recall, transfer, leaves of absence, compensation, and training. Gerente de Garantia de Calidad ¡Ven a trabajar con Tofurky! Somos el principal fabricante del país de proteínas de origen vegetal y quesos sin lácteos. Nuestra gama de más de 35 productos se puede encontrar en más de 25 000 supermercados en América del Norte, el Reino Unido y Australia. Tenemos la misión de borrar el mito de que las personas tienen que elegir entre disfrutar de una comida sabrosa O cuidarse a sí mismas y al planeta. Podemos hacer ambas cosas. Tofurky está buscando un miembro del equipo de Gerente de control de calidad para unirse a nuestro Equipo de control de calidad. El Gerente de control de calidad supervisa el sistema de calidad y seguridad alimentaria en las instalaciones propiedad de la empresa. Esto incluye supervisar la implementación y el mantenimiento del Plan HACCP de la empresa, el cumplimiento de BRCGS, el cumplimiento de FDA y las Buenas Prácticas de Manufactura. El gerente de control de calidad es el líder del equipo de control de calidad centrado en las operaciones y el equipo de saneamiento. Trabajan regularmente con el personal y los líderes multifuncionales para abordar las brechas y las oportunidades de mejora en los programas de inocuidad de los alimentos y visitan con frecuencia las áreas de producción para observar y resolver problemas. Este rol requiere tenacidad, una sólida comprensión de las prácticas de control de calidad, los fundamentos de la seguridad alimentaria, la resolución de problemas, el pensamiento crítico y un enfoque de trabajo en equipo. Requiere habilidades de gestión de programas de alto nivel, equilibradas con tiempo activo en la planta. Incluye responsabilidades:

Sabemos que eres valioso y trabajaremos duro para mantenerte desafiado. El candidato calificado recibirá:

Cómo aplicar: Envíe la solicitud y cargue su currículum en línea en https://tofurky.com/careers/ The Tofurky Company valora una fuerza laboral diversa. Se recomienda encarecidamente a las mujeres, las personas de color, las personas con discapacidades y los miembros de la comunidad LGBTQ que presenten su solicitud. Actualmente, The Tofurky Company no apoya el procesamiento de inmigración ni proporciona patrocinio de Visa. Todos los solicitantes deben poder proporcionar prueba legal de su elegibilidad para trabajar en los EE. UU. The Tofurky Company brinda igualdad de oportunidades de empleo (EEO) a todos los empleados y solicitantes de empleo sin distinción de raza, color, religión, sexo, origen nacional, edad, discapacidad o genética. Además de los requisitos de la ley federal, The Tofurky Company cumple con las leyes estatales y locales aplicables que rigen la no discriminación en el empleo en todos los lugares en los que la empresa tiene instalaciones. Esta política se aplica a todos los términos y condiciones de empleo, incluido el reclutamiento, la contratación, la colocación, la promoción, la terminación, el despido, el retiro, la transferencia, las licencias, la compensación y la capacitación. Job Location - Anchor Way - Hood River, OR

Position Type - Full Time Education Level - 2 Year Degree Travel Percentage - None Job Shift - Day Job Category - QA / Quality Control Come work with Tofurky! We are the Nation’s leading manufacturer of plant-based proteins and dairy-free cheeses. Our range of 35+ products can be found in more than 25,000 grocery stores throughout North America, the UK and Australia. We’re on a mission to erase the myth that people have to make a choice between enjoying tasty food OR taking care of themselves and the planet. We can do both. Tofurky is looking for a Compliance Specialist team member to join our Quality Assurance Team. The Compliance Specialist supports company compliance to certifications and regulatory requirements by assisting with verification, validation, and program development. They perform inspections and internal audits with a focus on compliance and work with all departments in resolution of findings. This position is an expert in the certification standards and regulatory requirements and assists during audits to provide evidence of conformance. The coordinator takes the pulse of these programs and provides feedback to management on current state and areas for improvement through observation and metrics. The coordinator has scientific background and the ability to design and carry out trials, testing and data analysis. The role does not directly supervise staff, but performs as a leader in the organization, helping promote food safety and compliance to these programs. This role initiates improvement efforts cross-functionally and helps educate staff on food safety programs and fundamentals. This role works within the QA department, primarily independently with frequent QA team and cross-functional interactions. Responsibilities Include:

What skills and education you’ll need:

What we’ll do: We know you’re valuable and we’ll work hard to keep you challenged. The qualified candidate will receive:

Currently, The Tofurky Company does not support immigration processing or provide Visa sponsorship. All applicants must be able to provide legal proof of their eligibility to work in the U.S. The Tofurky Company values a diverse workforce. Women, people of color, people with disabilities, and members of the LGBTQ community are strongly encouraged to apply. The Tofurky Company provides equal employment opportunities (EEO) to all employees and applicants for employment without regard to race, color, religion, sex, national origin, age, disability, or genetics. In addition to federal law requirements, The Tofurky Company complies with applicable state and local laws governing nondiscrimination in employment in every location in which the company has facilities. This policy applies to all terms and conditions of employment, including recruiting, hiring, placement, promotion, termination, layoff, recall, transfer, leaves of absence, compensation, and training. ¡Ven a trabajar con Tofurky! Somos el principal fabricante del país de proteínas de origen vegetal y quesos sin lácteos. Nuestra gama de más de 35 productos se puede encontrar en más de 25 000 supermercados en América del Norte, el Reino Unido y Australia. Tenemos la misión de borrar el mito de que las personas tienen que elegir entre disfrutar de una comida sabrosa O cuidarse a sí mismas y al planeta. Podemos hacer ambas cosas. Tofurky está buscando un Especialista de Cumplimiento de Calidad para unirse a nuestro Equipo de Control de Calidad. El Especialista de Cumplimiento respalda el cumplimiento de la empresa con las certificaciones y los requisitos reglamentarios al ayudar con la verificación, la validación y el desarrollo del programa. Realizan inspecciones y auditorías internas con un enfoque en el cumplimiento y trabajan con todos los departamentos en la resolución de hallazgos. Esta posición es un experto en los estándares de certificación y los requisitos reglamentarios y ayuda durante las auditorías para proporcionar evidencia de conformidad. El coordinador toma el pulso de estos programas y proporciona retroalimentación a la gerencia sobre el estado actual y las áreas de mejora a través de la observación y la métrica. El Coordinador tiene formación científica y la capacidad de diseñar y llevar a cabo ensayos, pruebas y análisis de datos. El rol no supervisa directamente al personal, pero se desempeña como líder en la organización, ayudando a promover la seguridad alimentaria y el cumplimiento de estos programas. Este rol inicia los esfuerzos de mejora de forma transversal y ayuda a educar al personal sobre los programas y fundamentos de seguridad alimentaria. Este rol funciona dentro del departamento de control de calidad, principalmente de forma independiente con un equipo de control de calidad frecuente e interacciones multifuncionales. Incluye responsabilidades:

Qué haremos: Sabemos que eres valioso y trabajaremos duro para mantenerte desafiado. El candidato calificado recibirá:

En Tofurky, no todos tenemos exactamente las mismas creencias sobre la dieta, la sostenibilidad o lo que va mejor con las papas fritas. No somos unicultural (y nos gusta que sea así). Pero todos podemos respaldar nuestra misión de respeto: ya sea respeto por nuestro planeta compartido, por todas las especies, por la salud humana o por nuestra comunidad y fuerza laboral. Cómo aplicar: Envíe la solicitud y cargue su currículum en línea en https://tofurky.com/careers/ The Tofurky Company valora una fuerza laboral diversa. Se recomienda encarecidamente a las mujeres, las personas de color, las personas con discapacidades y los miembros de la comunidad LGBTQ que presenten su solicitud. Actualmente, The Tofurky Company no apoya el procesamiento de inmigración ni proporciona patrocinio de Visa. Todos los solicitantes deben poder proporcionar prueba legal de su elegibilidad para trabajar en los EE. UU. The Tofurky Company brinda igualdad de oportunidades de empleo (EEO) a todos los empleados y solicitantes de empleo sin distinción de raza, color, religión, sexo, origen nacional, edad, discapacidad o genética. Además de los requisitos de la ley federal, The Tofurky Company cumple con las leyes estatales y locales aplicables que rigen la no discriminación en el empleo en todos los lugares en los que la empresa tiene instalaciones. Esta política se aplica a todos los términos y condiciones de empleo, incluido el reclutamiento, la contratación, la colocación, la promoción, la terminación, el despido, el retiro, la transferencia, las licencias, la compensación y la capacitación. How to apply:Please submit your application and upload your resume online at https://tofurky.com/careers/ July 2023 Start | $18/hour

Wheat Marketing Center is seeking a seasonal Laboratory Assistant in wheat testing and technical support of projects and research. In addition, this role will work with the Assistant Operations Manager and existing Laboratory Assistants during the crop quality season (early July to end of September) to meet deadlines and achieve goals. Provide support for technical courses and facility tours. This position has the potential to become a full time permanent position. Employment Duration:

JOB DESCRIPTION

Job Title: Research and Development Manager Reports to: Director of Product Innovation Department: Marketing Classification: Exempt; Salary Shift: 8-hour Day APPLY HERE Our success begins and ends with our people. We embrace diverse perspectives and value unique human experiences. We are proud to be an equal opportunity employer that celebrates the diversity of the communities where we live and do business. Applicants for our positions are considered without regard to race, ethnicity, national origin, sex, sexual orientation, gender identity or expression, age, disability, religion, military or veteran status, or any other characteristics protected by law. Company Overview: At Bob’s Red Mill, we inspire joy with wholesome foods. Since 1978, we have been leading the natural foods industry by providing our customers with good food that makes them feel great. Wholesome means ensuring our food is of the highest quality, empowering and supporting our diverse group of employee owners, respecting our planet, and bettering our communities. We believe that joy is for everyone. Purpose: To inspire joy with wholesome foods. Values: Respect, Teamwork, Accountability, Determination Position Overview: The Research & Development Manager will play a vital role in bringing Bob’s Red Mill products to life and ensuring a best-in-class product experience in order to achieve our exponential growth and drive forward our purpose of inspiring joy with wholesome foods. This position leads and is the voice of food science technology in partnership with the Director of Innovation Marketing for the company, supporting the direction for the team, establishing R&D processes, and helping to solve the unsolvable. This role will focus on developing new and reformulated products from concept through commercialization. This role is cross-functional working closely with Supply Chain, QA, Sustainability, Operations, Engineering, and Co-Manufacturers to help the company meet changing consumer needs and create new revenue opportunities. Essential Job Functions: • Leads the Research & Development team in developing new products and product improvement initiatives, including designing and developing against complex product development projects that have significant impact on the business and strategic objectives. • Supports end-to-end product development program, product renovation, and cost reduction projects across multiple product categories while considering important technical issues including food safety, shelf stability, profitability, scalability, and sustainability. • Leads sensory and product development research to ensure delivery against key performance benchmarks including category, competitive, brand, and concept product attributes. • Utilize consumer research to support decision making in new product and product improvement initiatives. • Create and maintain detailed project status reports, product specifications, production processes, plant trial protocols, and other documentation. • Works in partnership with our Co-manufacturing Manager and Supply Chain teams to foster and maintain relationships, support onboarding of all co-manufacturing partners and leads major initiatives that address complex functional and technical issues. • Identify and evaluate primary (in-house) and secondary (co-manufacturer) manufacturing locations for specific project needs, and support site assessments as needed. • Constantly tracks new functional or other new ingredient options for unique finished product attributes, product improvement and cost reduction opportunities. • Identify cost saving opportunities, raw material consolidation/optimization, technical challenges, and manufacturing efficiencies and work towards implementation through cross-functional collaboration with respective departments. • Works collaboratively with Quality Assurance and Operations teams to ensure that all projects and activities meet standards for GMP, HACCP, FSMA and other relevant food safety requirements. • Effectively builds relationships with other department leaders and team members to reach project goals. • Complies with all company policies and procedures and operates all equipment in a safe and food-safe manner. • Complies with Bob’s Red Mill food safety policies and procedures including adherence to FDA regulations and Good Manufacturing Practices (GMPs). • Other tasks and duties as may be assigned. Supervisory Responsibilities: • This incumbent will have direct oversight of up to 3 individuals. • This position will report to the Director of Innovation Marketing. Knowledge, Skills and Abilities: • Highly experienced food scientist with previous food manufacturing experience, strong relationship management, project management and strategic thinking. • Experience with new product development, product renovation, quality assurance, regulatory compliance, and scaling commercialization. Experience working with developing new products both in-house and with co manufacturers. • Experience managing teams and demonstrated ability to lead and develop a department and department staff members. • Strong understanding of ingredient functionality, food safety and regulatory affairs in the USA. • Strong project management skills, including adeptness with organizing numerous projects simultaneously and track record of consistently meeting critical deadlines • Ability to work effectively on a cross-functional team with direct communication, strong emotional intelligence and respect • An exceptional degree of drive, resilience, and motivation to solve complex technical problems. Ability to adapt to change and frequent realignment of priorities. • Excellent command of Microsoft Office Suite, including Outlook, Word, PowerPoint, and Excel. Knowledge of Microsoft 365, Google Sheets, Docs, Slides, and ESHA Genesis • Willing to travel up to 25% of the time domestically and occasionally internationally, as required by project needs • Demonstrates Respect, Teamwork, Accountability, and Determination. Preferred: o Experience with Stage Gate project management processes o Quality assurance experience o Experience developing special products or pack sizes for club stores o Familiarity with Bob’s Red Mill product line o Interest in natural foods and healthy eating Qualifications: • B.S. or M.S in Food Science or related disciplines • 5+ years of food product development with commercialization experience across multiple technologies and product types • Experience working with Operations, Quality Assurance, Supply Chain, Engineering, or Co-Manufacturing Physical Demands: • This position requires ability to sit for up to approximately 2 hours at a time. Work Environment: • The primary environment for this position is an office setting, with time spent in production facilities, labs and test kitchens as needed. What you should know: Our success begins and ends with our people. We embrace diverse perspectives and value unique human experiences. We are proud to be an equal opportunity employer that celebrates the diversity of the communities where we live and do business. Applicants for our positions are considered without regard to race, ethnicity, national origin, sex, sexual orientation, gender identity or expression, age, disability, religion, military or veteran status, or any other characteristics protected by law. |

Archives

May 2024

|